Environment Management

Sinochem International has formulated documents including an Environmental Protection Management Measures, Environmental Protection Responsibility System and Clean Production Management Standard, and has established an environmental management system covering all business units, set up a full-staff, full-process, full-position environmental risk detection, control and management mechanism. We performed environmental impact assessments on new, modified and expanded projects, and performed regular onsite environmental management monitoring and inspections as well as follow-ups of rectifications to hidden hazards. We are also taking “Creating Green Plant” as a key starting point and continuously promoting refined management of environmental protection..

Pollution Prevention

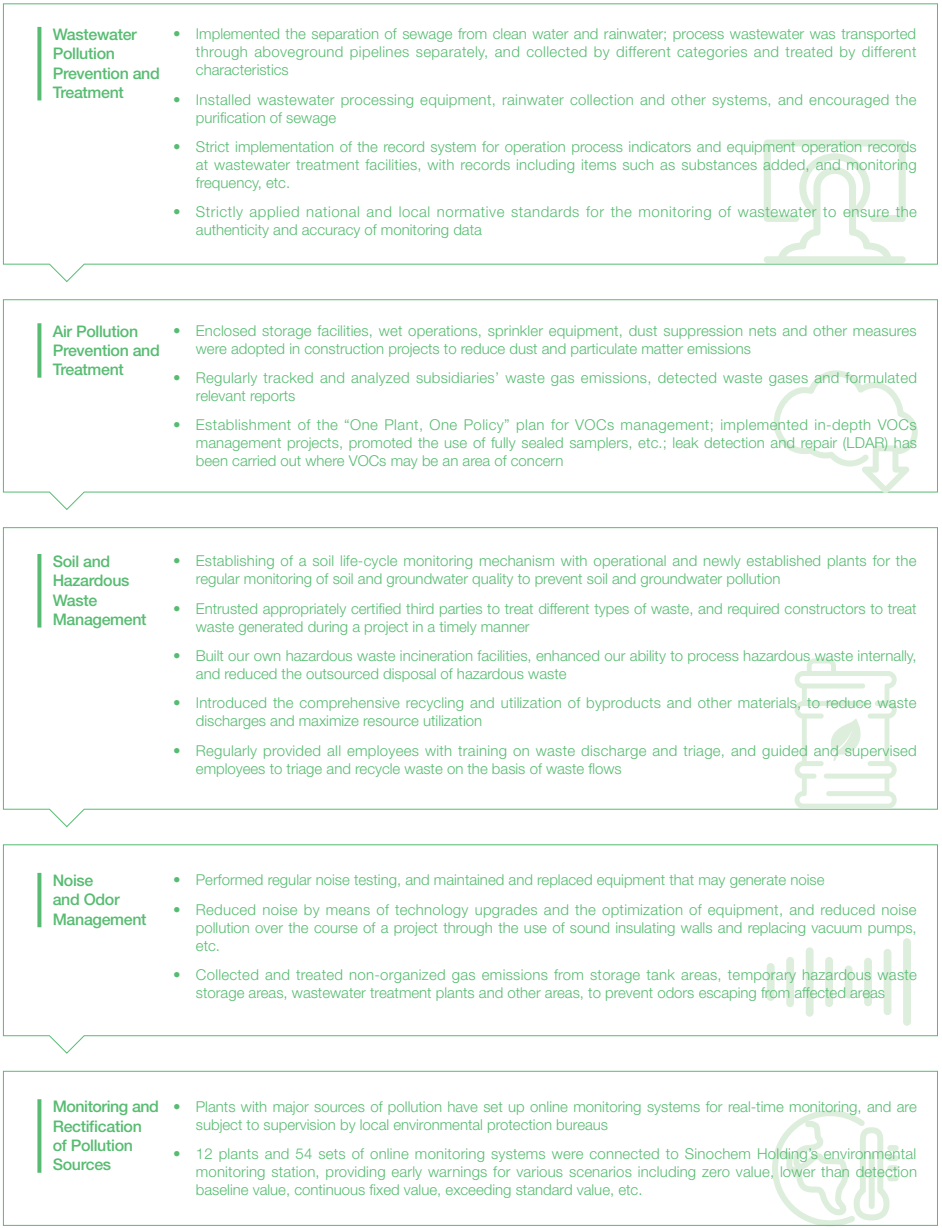

The company has formulated emission control standards for waste gas, wastewater, solid waste, soil pollution and other pollutants, and insists on a concept of environmental protection throughout the entire production life cycle. Green and clean production technologies are promoted at source, and close attention is paid to the implementation in the production process. With a moderate rise in investment in end treatment, we energetically promoted the development of end treatment capabilities, in order to ensure that waste water, waste gas and other discharges from subsidiaries are significantly below standard limits, and to prevent the occurrence of environmental pollution incidents.

The company has been introducing new technologies, improving pollutant processing capabilities and measures, and continued to carry out special treatment of non-organized emissions in order to ensure that “three-waste” discharges comply with standard limits. Meanwhile, we carried out environmental credit evaluations and environmental protection verifications to promote good environmental protection practice, and continued to promote the sound operation of environmental protection management systems, and effectively control pollution risks.

Energy Conservation and Emissions Reduction

The company has formulated documents including Energy Management and Climate Change Policy, Administrative Measures for Energy Conservation and Clean Production Management Standard. We have improved process-wide energy conservation management covering clean energy use, process equipment upgrades, clean technology innovation and other areas. We also have promoted resource recycling and greater energy efficiency by means of energy conservation assessments, energy audits, energy balance testing and other measures.

Water Resource Management

The company has formulated a Water Resource Management Policy and continued to promote water management. We implemented efficiency enhancing initiatives focusing on key water-using enterprises and carried out regular analyses and audits of rational water use to continuously improve the recycling rate of water resources and reduce the consumption of fresh water through new technology. All the company’s water resources are derived from the municipal water supply, and neither water intake nor sewage discharge has had a significant impact on the water source.

Environmental Advocacy

The company continues to develop green plants and upgrade its existing green plants, and to promote green innovation along the entire production process from equipment and raw material procurement to packaging and production with the goal of building an efficient, clean, low-carbon, and circular green manufacturing system, and closely and carefully integrates environmental management into the entire production process.

The company attaches great importance to biodiversity conservation and has carried out EIAs and biodiversity impact studies in the project pre-feasibility study stage and plant site selection stage to fundamentally eliminate and reduce its impact on the ecosystem. All of the company’s plants and projects are located far away from biological reserves, and all production and manufacturing processes have had no significant impact on the ecological environment.

The company encourages the use of green processes, reductions in raw material consumption, and promotes the recycling of raw materials and packaging materials. We achieve the recycling and reuse of input materials by optimizing processes and technologies, we use environmentally friendly raw materials, and reduce the resource and energy consumption of products and materials; we encourage the replacement of hazardous or toxic raw materials with less hazardous or toxic alternatives, and use clean production models to reduce the production of hazardous waste and toxic substances.

As an advocate of sustainable consumption, the company utilizes recyclable packaging materials, etc., for its product packaging; works to reduce resource and energy consumption for products and materials in storage, transportation, and other process links; has worked to establish a packaging recycling management system; realizes packaging recycling monitoring along its entire production process; and minimized packaging pollution.

In 2022, the company formulated a Recyclable Packaging Plan to promote the introduction of recyclable packaging materials both at home and with its suppliers. Using dimensional statistics ranging from reducing the use of packaging materials, the preferred use of packaging containers made from reusable materials, and the recycling of packaging containers, inter alia, we identified project cases on promoting carbon emission reductions using packaging recycling methods by itself and its suppliers. As of the end of 2022, a total of 14 recycled packaging material projects had been implemented, in which 4 projects were implemented by suppliers, generating economic benefits exceeding 50 million yuan.

KPIs in 2022:

● Total investment in environmental protection: 512 million yuan

● Environmental pollution incidents: 0

● Compliance rate of exhaust gas, wastewater discharge, and industrial enterprise noise: 100%

● Compliant solid industrial waste disposal rate: 100%

● Percentage of workplaces with environmental risk assessments: 100%

● Percentage of subsidiaries that have received environmental management system certification: 100%

● Major leak incidents on record: 0

● Hazardous waste disposed of by contractors: 46,658 tons

● Total investment in energy conservation: 89.65 million yuan

● Green plants by the standards of the Ministry of Industry and Information Technology: 5

● Green plants by the standards of the China Petroleum and Chemical Industry Federation:10

● Green plants according to provincial standards:4

● Ratio of operations with local community participation, impact assessments and development plans:100%