Intrinsic Safety

Sinochem International has increased investments in intrinsic safety by focusing on risk management and control. The company applies intrinsic safety to new, modified and expanded projects from the design stage onward, and performs work hazard analyses and reaction risk assessments on projects and equipment, as well as comprehensive investigations of factors contributing to occupational disease, improving employee safety protection levels, evaluating and improving the implementation of any proposal for improvement, in order to comprehensively improve the level of intrinsic safety.

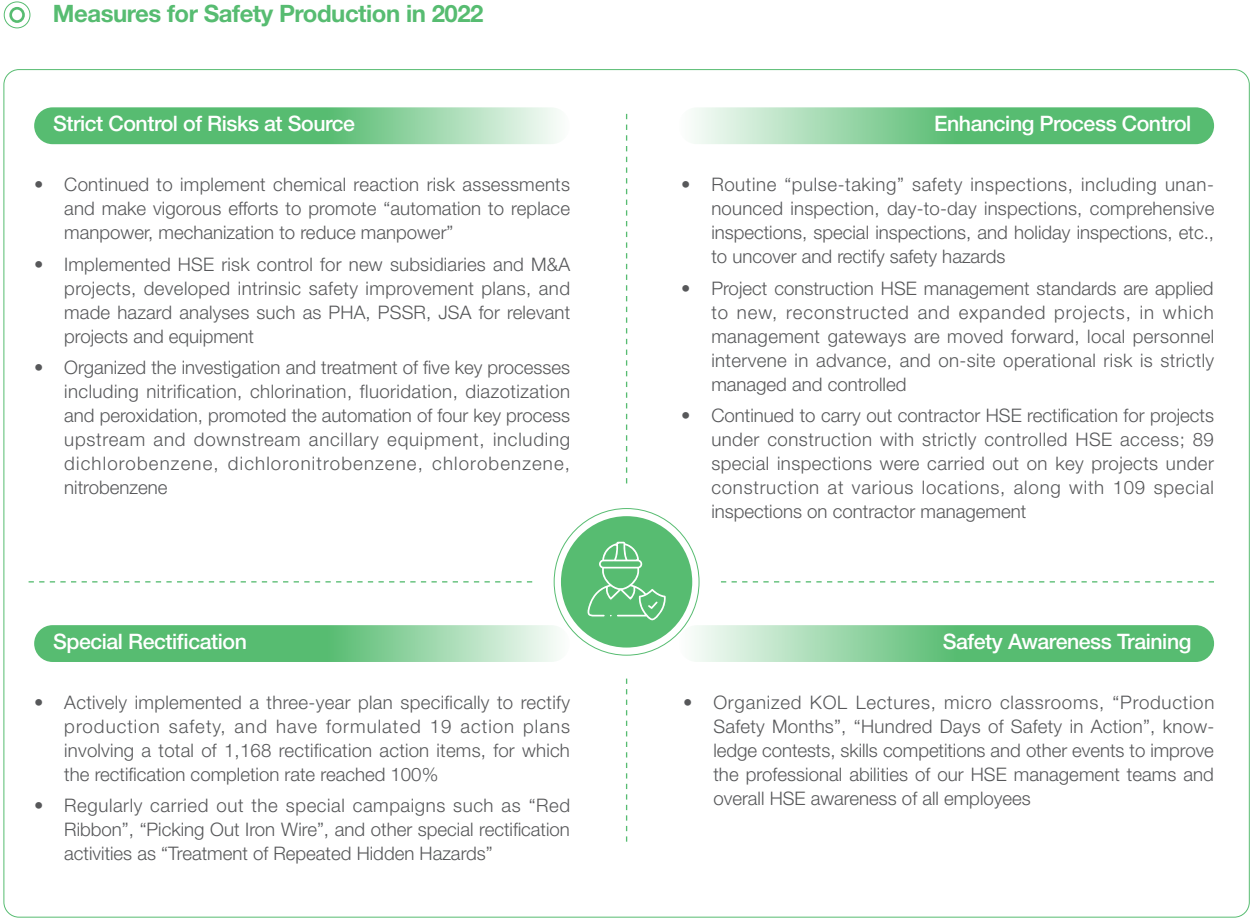

Safety Production

The company has formulated the policy of Management Measures for Safe Production, Work Permit Control Standards, fully implemented safety production deployment and safety production responsibility. With increased investment in intrinsic safety, we enhanced risk management and investigation of hidden hazards, established red lines for safe production, and resolutely prevented major safety accidents.

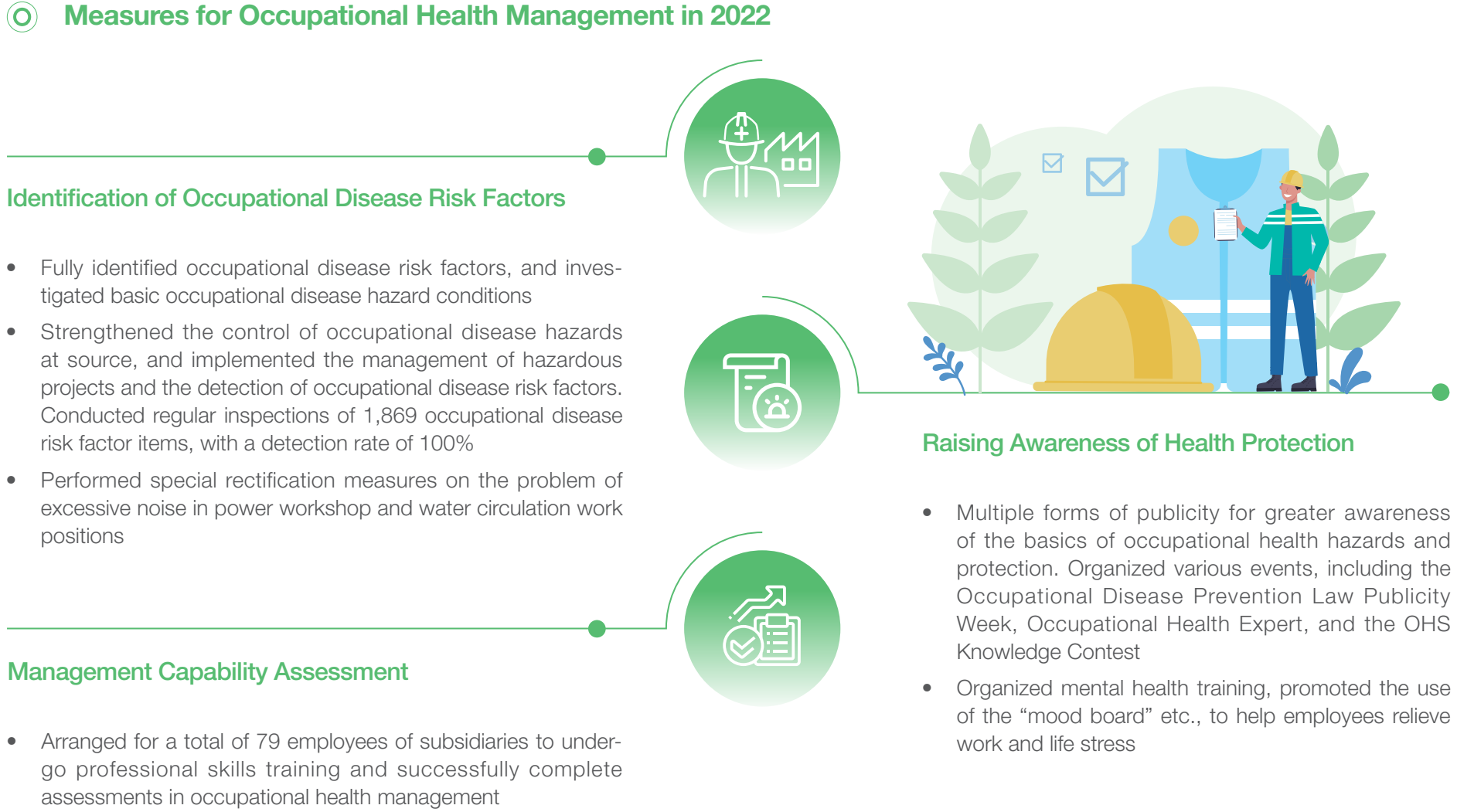

Occupational Health

Sinochem International has formulated the Occupational Health Management Measures and worked continually to improve its occupational health and safety management system. The company performs annual identifications and assessments of occupational disease risk factors, promotes the remediation of occupational disease hazards, and organizes a range of events including “Occupational Health Talent” and “Creating Healthy Enterprise” in order to eliminate all potential occupational health risks, and improve the occupational health to a higher level.

The company has signed Collective Labor Contract with the labor union that addresses issues such as employee occupational health and safety protection. The HSE Committee, which comprises the chairman of the labor union, frontline employees and worker representatives, makes decisions on health and safety-related issues on behalf of all employees and works to ensure that our employees’ right to know and participate in decision-making are upheld.

The company has formulated and improved the Emergency Plan for Production Safety Incidents and Emergency Response Plan for Public Health Emergencies and other plans to consolidate the foundations for emergency protection. We arranged for all subsidiaries to organize systematic emergency capability assessments and on-site inspections, conducted unscripted drills to test the emergency response capabilities, thus enhancing the coordinated emergency rescue and emergency response capabilities at all levels during emergency situations.

Chemicals Management

Sinochem International has adhere to the policy of “Safety First, Prevention Crucial, Integrated Management” and formulated HSE Risk Management and Control Standards for Hazardous Chemicals, Risk Control Standards for Major Hazard Sources of Hazardous Chemicals and other systems as well as a position safety responsibility mechanism. The company established a monitoring system for the entire process governing the procurement, loading and unloading, storage, transport, processing and disposal of hazardous chemicals.

Based on the Hazardous Chemicals Procurement Management Evaluation Plan, the company also regularly conducts risk assessments with its hazardous chemical suppliers which cover core elements such as qualifications review, hazardous chemical transportation, etc. This ensures control and compliance when it comes to raw material procurement and the transportation of hazardous chemicals.

KPIs in 2022:

● Investment in safety and health measures: 228 million yuan

● Key equipment risk control rate: 100%

● Employee HSE training participation rate:100%

● Production safety accidents of level general and above (including contractors): 0

● Employee occupational health examination rate: 100%

● Occupational health management filing rate: 100%

● Allocation and correct use rate of workplace protection equipment: 100%

● Percentage of workplaces that have undergone employee health and safety risk assessments:100%

● Percentage of subsidiaries that have received occupational health and safety management system certification: 100%

● Occupational disease cases in the whole year: 0

● Emergency drills conducted: 306, Participants: 20,136